The company is specialised in the construction of OmniPower sound source, acoustic noise sources, dodecahedron speaker, directional speaker, tapping machines.

TECHNICAL NOTES ON OMNIDIRECTIONAL SOUND SOURCES

Thanks to careful design, we have placed all the electronic circuits inside the spherical sources. Making these instruments extremely compact.

Twelve loudspeakers, the digital amplifier and a sophisticated generator are packed into a single object. The resulting practicality is maximum! Ideal for those who have to take measurements in different places each time.

To operate the omnidirectional sound source, simply supply it with mains voltage or, if available, with battery.

All that is needed is to turn on the power switch. With the remote control, you activate even remotely, all functions for perfect operation, of the sound sources. All models have an equalizer, which linearly extends the frequency response from 50 to 20,000 Hz. There is an auxiliary input in all of them, for playing external signals. A bluetooth input is also optionally available, with which any signal from Notebook, smartphone or tablet can be sent to the source. It should be considered that the bluetooth range of devices on the market is usually only 10 meters. Each sound source is available in two versions: one powered by battery and current, the other, more economical, powered only by 230 Vac mains ( 115 Vac US version). The batteries are extremely lightweight and provide more than an hour of runtime at full power.

Remote control

The function of the remote control is not limited to ” Play / stop ” of the source, but enables all functions via its 16 buttons. Among them:

- Recall of 8 different types of noise

- 4 calibrated power levels with direct access

- Volume adjustment in calibrated 2 dB steps

- Memory storage of the last noise used and its volume level

- Passing though walls and floors

- Power source: 2 AA alkaline batteries. Autonomy over 2 years.

Noise generator

Main noises available in all omnidirectional sound sources.

- White noise: Pseudo-random

- Pink noise: Pseudo-random

- Fast white noise: Alternative to the previous one (greater precision)

- Fast pink noise: Alternative to the previous one (greater precision)

- Sine sweep: is a variable frequency sinusoidal signal, with exponential frequency variation over time. It generates a higher pressure than the pink noise by about 10 dB.

- Impulsive noise: reproduces a noise similar to a balloon bursting or a gunshot.

All noise loaded in our omnidirectional sound sources are available with two frequency extensions of (100 to 8,000 ) Hz, specifically for measurements in buildings, and (50 to 20,000 ) Hz for more refined measurements in theatres, concert halls, etc.

DESCRIPTION OF THE ACCOMPANYING NOISES

White noise and Pink noise are the classic pseudorandom-white and pink noise universally used.

Fast white noise and Fast pink noise are alternatives to the former but are more precise. They consist of a digital sequence generated by a shift register. They allow the frequency response to be read on the sound level meter in real time, without the need to acquire the measurement for a few seconds. Thirds of octave are stable, they do not oscillate, but appear stationary on the sound level meter’s display and allow an instantaneous accurate reading. It only takes 0.2 seconds to acquire the measurement. These noises are particularly useful for sound insulation measurements between two neighbouring rooms. In the emitter environment they simplify the search for the best positions in which to take measurements with the aim of avoiding those points where nodes and antinodes alter the frequency response too much. The aim is to obtain the average of the frequency response measurements with sufficient linearity to satisfy the regulations. This is further facilitated by the ‘linear responce’ equaliser, which linearises the frequency response of the omnidirectional sound source.

Sine sweeps consists of a sinusoidal signal whose frequency initially at 50 Hz increases exponentially until it reaches 20,000 Hz after 20 seconds. It allows measurement of reverberation time with (Hadamard + deconvolution) ( ISO 18233-2006). Since it is little affected by background noise, it allows measurements to be made in noisy environments(up to 80 /85 dB) where with pink noise and white noise it would not be possible. It provides at least 10 dB more power to the source than pink noise.

Impulsive noise. This is an important exclusive new feature in our new sources. By pressing button 3 on the remote control, a powerful impulsive noise is reproduced after 3 seconds. It takes only 18 seconds to reproduce 6 impulses necessary to acquire the entire reverberation time measurement. According to the current regulations, it is possible to keep the impulsive sound source in one position to take the measurement, and then move the sound level meter to six different points in the room. The 3-second pause between one impulse and the next is precisely for these movements.

It replaces (with greater precision and practicality) the clapper, the gunshot or the bursting balloon

Most importantly, it has none of their defects because :

1) the polar pattern is perfectly omnidirectional (because it is emitted from an omnidirectional source)

2) The frequency response is extended to the entire audio band.

3) The pulses generated are all equal and perfectly repeatable.

It is easy to operate individually without the help of others.

These are currently the only sound sources on the market that allow reverberation time to be measured in all possible ways.

1) Interrupted noise (Sabine).

2) Sine sweep (Hadamard + deconvolution) ISO 18233-2006 the most accurate and precise

3) Impulsive noise (Schroeder) Very fast measurement of reverberation time using the method described above.

Loudspeakers and power applied to omnidirectional sound sources

Our goal was not to build a powerful instrument, neglecting all its implications.

We focused on the reliability, quality and durability of the instrument over the years.

We developed systems with the highest efficiency, to achieve high pressures while applying relatively low power.

The design was more complex, but the benefits obtained are innumerable.

We apply 150 W Rms power to the smallest sources and 300 W Rms to the largest ones; even if they withstand much higher powers. In this way, even at maximum power the voice coil of the loudspeakers never exceeds a temperature of 70 to 80 degrees (we will explain later how important this is). The elastic parts of the loudspeakers are never overstressed, allowing the instrument to maintain its characteristics over time. It thus remains compliant with ISO standards. Many acousticians still use our omnidirectional sources, purchased twenty years ago, because they are still efficient and compliant with the standard.

If we had applied double or quadruple power (as other manufacturers do) we would have obtained an increase in LW power of 3 or 6 dB respectively. The noise emitted by the source would have been extremely powerful, but we would have greatly reduced the life and reliability of the omnidirectional source. The voice coil of the loudspeaker with so much power to dissipate, would have strongly overheated, greatly deteriorating the stability of the acoustic source. Because as the voice coil heats up, the power supplied by the amplifier is considerably reduced for the following reason: the maximum temperature borne by the voice coil of a loudspeaker is approximately 220 to 230 degrees. At this temperature, the electrical resistance of the copper from which the voice coil is made is approximately three times that at room temperature.

The power supplied by the amplifier is given by the square of its output voltage, divided by the value of the loudspeaker resistance Pt = V2/R. Thus, if the resistance R of the loudspeaker coil triples its value, the amplifier will supply it with 1/3 of the initial power with an inevitable loss of power and therefore of pressure of 4 – 5 dB; unacceptable for a measuring instrument.

This is particularly noticeable in sound sources that only sustain maximum power for a few minutes. This is due to an excess of power being applied to the loudspeakers, or because they are undersized.

In our sources, the various components, in particular the magnetic assembly of the loudspeakers, as well as being low on power, are constantly ventilated to reduce and even out the temperature as much as possible.

This ensures a long product life, especially for the loudspeakers which, being mechanical objects, are more prone to wear and failure. Large applied powers generate large excursions of the cones, which put a strain on the elastic parts of the loudspeakers (spider and surround edge) altering their characteristics and considerably reducing their life. With low powers involved, it is also easy to power the amplifier with small batteries that are light enough to be hung under the tripod. As in the adjacent photo).

The power that the amplifier sends to the loudspeakers in the reproduction of white and pink noise is distributed simultaneously over the entire frequency spectrum. In contrast, in the reproduction of sine sweep, it concentrates all its energy on a single frequency that varies over time and thus reaches a much higher level of pressure. In amplifiers and loudspeakers, the electrical and mechanical stresses double in intensity. Many commercially available audio systems, driven at maximum power with the sine sweep, become irreparably damaged.

The power applied to our sound sources is relatively low (150 – 300 W Rms) and the components are oversized so that our loudspeakers have no difficulty withstanding it up to maximum power.

We are probably the only manufacturer in the world to provide sine sweep as part of the omnidirectional sound source.

Why is the frequency response in our sources extended from 50 – 20,000 Hz?

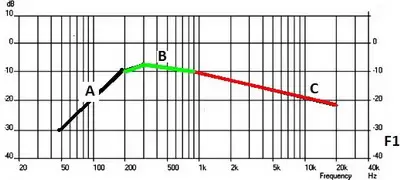

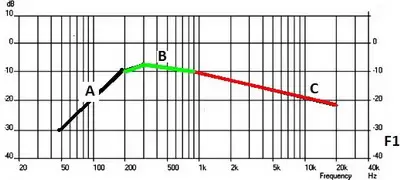

Assuming to have an ideal speaker with a perfectly linear frequency response over the entire audio spectrum, if the same were assembled in a loudspeaker, similar performance would be achieved. On the contrary, assembling 12 speakers equal to the previous one in a dodecahedron-shaped (or spherical) loudspeaker would not result in a linear frequency response, but in one very similar to that of Chart F1.

(A) Very low frequencies will be non-existent

(B) Mid frequencies will be linear

(C) High frequencies will be very attenuated.

This happens because:

At medium and low-mid frequencies (segment B chart F1) where the wavelength is greater than the physical dimensions of the sound source, all twelve speakers are in phase and their contribution adds up.

As the frequency increases, the wavelength decreases, the speakers become more and more directional, the even small distances between one speaker and the other create time delays and phase shifts, which lead to a considerable reduction in level as the frequency increases (C red line in Chart F1).

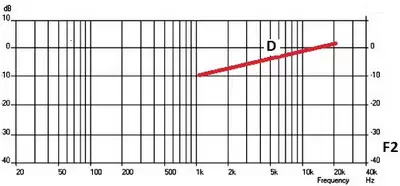

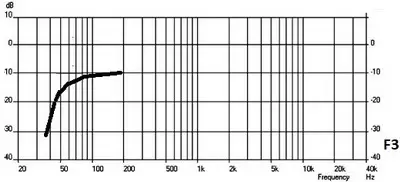

To achieve remarkable results instead of fitting commercial speakers, we designed our own speaker specifically for our needs. Thanks to a special combination of cone surround, edge surround, voice coil and magnet, we were able to construct a speaker with an upward frequency response (D chart F2); in practice complementary to the natural response offered by the dodecahedral shape C ( chart F1).

This compensates and makes the high frequency response linear. If the same speaker were used to play music it would perform poorly, in our case it improves high-frequency linearity, system efficiency and power output, particularly with white noise.

The lowest frequencies

In an sound source, built with commercial loudspeakers, it is not possible to reproduce low frequencies (50 – 100 Hz) with high power. This is because the volume of the dodecahedral source is too small. The way commercial loudspeakers are designed, the available internal volume should be 5 / 10 litres of air per loudspeaker. (This figure refers to 4 – 5 inch drivers commonly used in commercial dodecahedral sound sources). For twelve loudspeakers, you therefore need 50 / 100 litres of total volume. The internal volume of a sound source is 5 – 10 times smaller. Such a small volume of air offers great resistance to air compression which the loudspeakers can hardly overcome. Lower frequencies, which require a large cone excursion, are not reproduced because the loudspeaker does not have enough force to compress (and expand) the air contained inside the box (dodecahedron or sphere). See curve A in Chart F1

In the most serious cases, some manufacturers have had to attach a heavy and bulky subwoofer to the source.

Since we are one of the few sound source manufacturers to be able to design our own loudspeaker, we assemble a very powerful motor (magnet assembly, coil, air gap, etc.) on it. The same magnet is often used, especially in the USA, in the large Ø 46 cm (Ø 15 inch) woofers in huge concert loudspeakers.

We assemble it on a small 13 cm (5 inch) diameter driver. Giving so much ‘force’ to a commercial speaker reproducing music would make no sense, mounting it in our sources provides the force needed to compress (and expand) the air inside the box.

This and the appropriate choice of loudspeaker Qts and VAS combined with other measures extend the response to the lower frequencies (chart F3.)

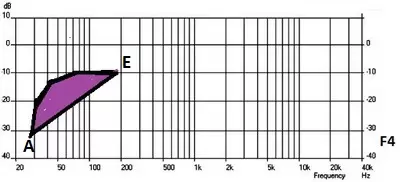

The purple area between curve A and the new curve E highlights the improvement at lower frequencies in the (Chart F4)

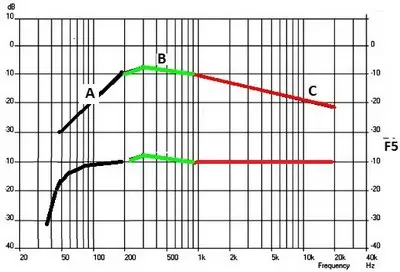

In chart F5 the upper part shows the typical response of an omnidirectional acoustic source . At the bottom, the graph shows how much the overall linearity has improved with the adjustments described above. This explains, in short, how we achieved the best performance.A subsequent tweak with internal equalisation further improved the frequency response of our omnidirectional sound sources.

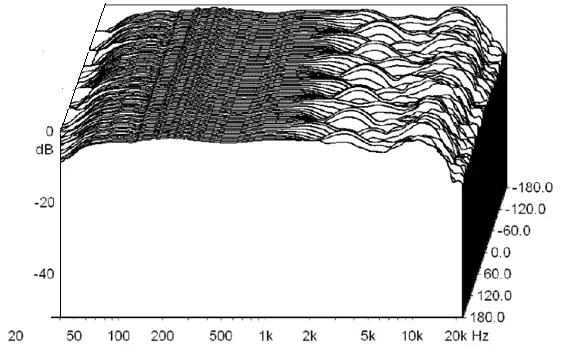

Real case Mod S103 (diverter in linear position ) Below there are 72 superimposed frequency responses performed in an anechoic chamber on a rotating base one every 5 degrees of rotation ( as per dedicated ISO standard )

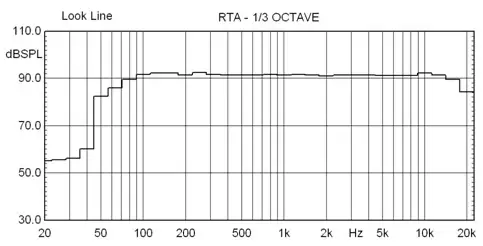

Average of the previous 72 frequency responses relative to the previous chart (Mod S103)

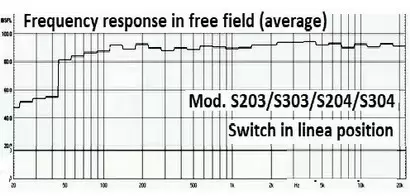

Same average relative to Mod S203 / S303

Transporting

Such objects by air is normally prohibited, because the strong magnetic field emitted by the source can interfere with the aircraft’s compass. With an additional 48 small magnets distributed on the surface of the sphere out of phase, we have lowered the magnetic field present on the outside of the sphere, making the sound source compliant with IATA flight regulations.

Batteries

At locations where measurements are taken, electricity grid is not always available. Each sound source is available in two versions: one battery and mains powered, the other more economical powered only by 230 Vac mains (115 Vac US version).

The batteries are very light, enough to be hung on the tripod and are equipped with instruments to assess the remaining autonomy.

They allow one hour of work at full power with white noise and 1.5 with pink noise, and over 1,000 impulsive noises for measuring reverberation time.

The acoustic source container.

We made the first prototypes with a 3D printer, we obtained a good aesthetic result, but the mechanical performance was very disappointing, no material allowed us to obtain aphonic and low-vibration structures. We therefore resorted to aluminium moulds, which allowed us to use a micro-cellular composite material that is particularly aphonic and can dampen resonances.

The spherical shape is absolutely the best to counteract vibrations and at the same time to eliminate diffractions caused by the edges (for these reasons we abandoned the dodecahedral shape).

As a result, the damping time of the sound sources is 1.5 thousandths of a second. This is the time it takes for the whole system to go from full power to fully off. Very long times could distort reverberation time measurements. The level of technology achieved by our sound sources is probably the highest commercially available.

The large quantities produced also allow us to offer very competitive prices

2-years warranty; that can be extended to 5 years. Batteries are excluded from the extension because they can be damaged in a short time if not used correctly. ( follow our instructions)